Applications

- Crystallisation plants

- Vaporisation plants

- Reactor loops

- Sludge recirculation

- Pumping stations

Advantages

- Robust construction – long service life

- Gentle transport

- Fiber repellent

- Saving energy – suction behavior

- Tough applications with corrosive fluids

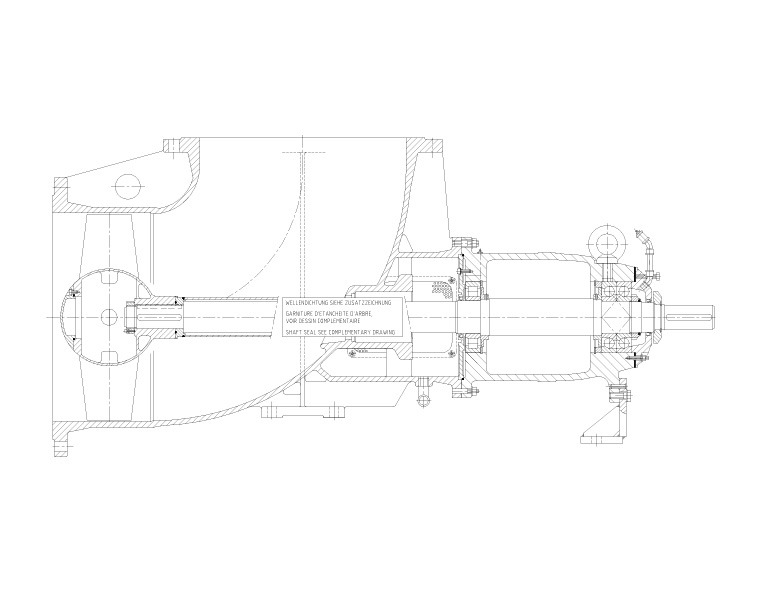

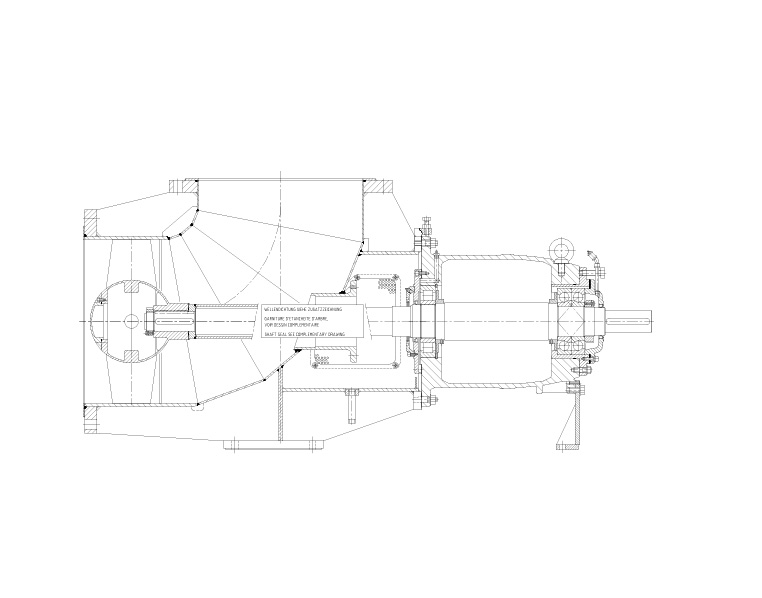

Design

RPG

Casted elbow in GGG 40, 1.4409, 1.4593 or 1.4588

Nominal dimensions:

DN 250 to DN 700

RPP

Welded elbow in

Steel 37, 1.4404, 1.4460, 1.4529, Monel, Hastelloy or other special materials

Nominal dimensions:

DN 250 to DN 1100

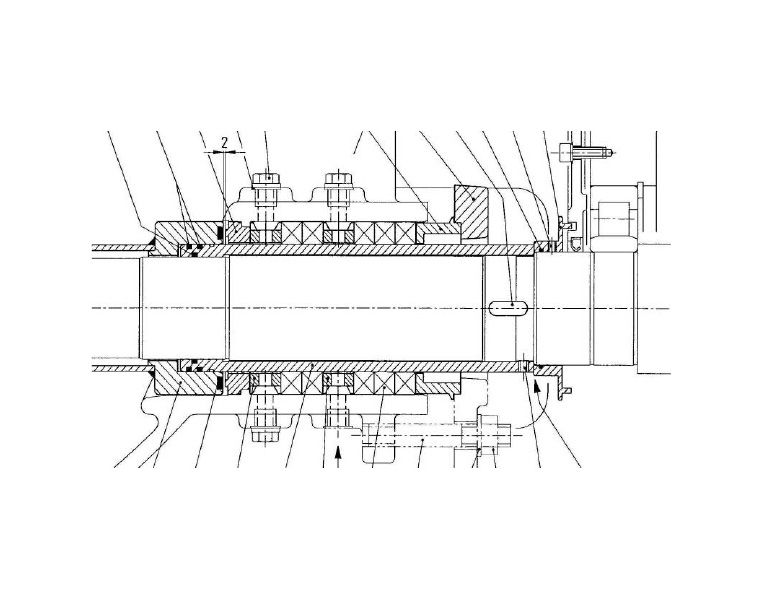

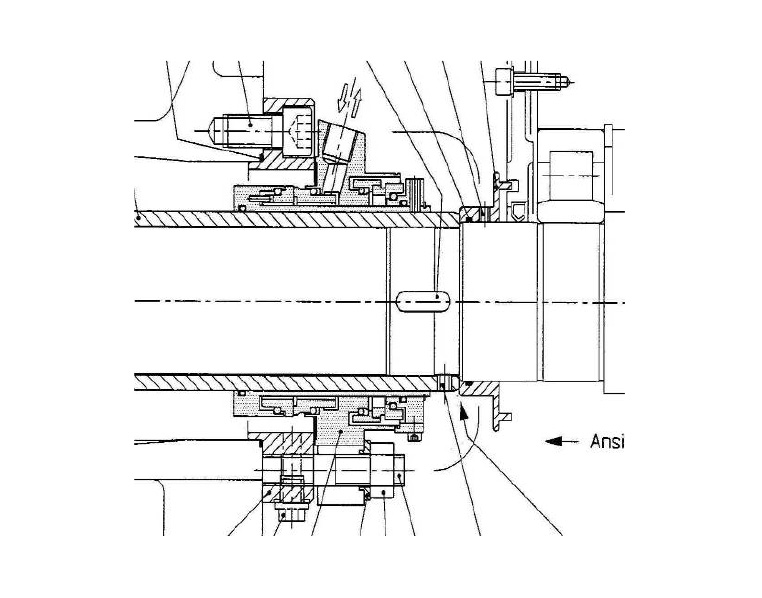

Shaft Sealing

Stuffing box with

Single barrier

Double barrier (hot liquids)

Stand still sealing

Double mechanical seal

Cartridge type

Easy to maintain and solid, due to springs outside of the liquid

Barrier: with quench or vessel system

Egger Elbow Propeller Pump DN 1300 Assembly

Have a look behind the scenes! Assembly of an Egger Elbow Propeller Pump size DN 1300 for the salt industry in our pump factory.

Axial propeller pumps for salt industry

In our production facilities in Cressier in the canton of Neuchâtel in Switzerland, many elbow propeller pumps for the salt industry have been manufactured in recent months. The production of two large axial pumps DN 900 (RPP 901 LB8.1) in Monel 400 and 411 was particularly challenging and interesting.

Titanium Axial Propeller Pump for the Salt Industry

In our production facilities in Cressier in the canton of Neuchâtel in Switzerland, many elbow propeller pumps for the salt industry have been manufactured in recent months. A special highlight was the production of an Egger axial flow pump in size DN 800 in titanium grade 12 (RPP 805 LB 7.2).

11 Elbow Propeller pumps for KCL in Laos

Egger provides a total of 11 Elbow propeller pumps to Vinachem in Vietnam.

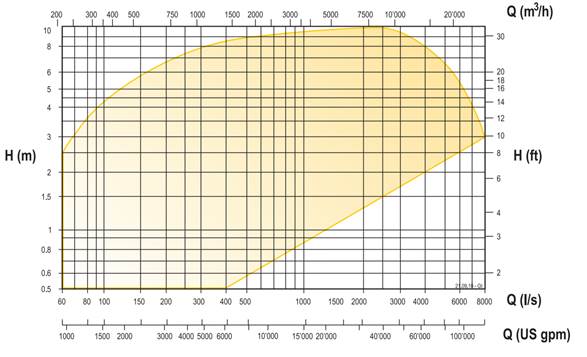

Successful performance test of the new Egger Elbow Propeller Pump generation

At the official test facility of the Centre Technique des Industries Mécaniques in Nantes (CETIM), two new Egger axial pumps of nominal sizes DN 800 and DN 900 were measured successfully.

Axial pumps for Munich sewage treatment plant

Large recirculation pumps for WWTP Gut Grosslappen, Munich (Germany).

The Best Pump Solution For Your Application

At Egger, we strive to reduce your operations budget by supplying our pump technology which has the lowest life cycle cost available. Factors affecting life cycle cost include initial purchase price, maintenance over the life of the pump, and energy consumed.